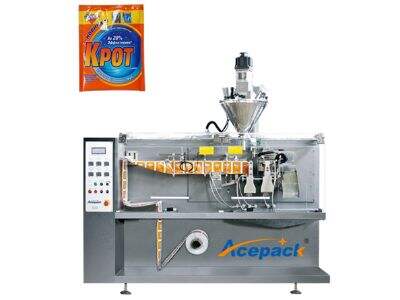

Obraz przedstawia Twoją fabrykę, która staje się szybsza i bardziej wydajna. Jeśli tak, maszyna pakująca w worki może być idealnym rozwiązaniem. Maszyny pakujące pomogą Ci pakować przedmioty szybciej, oszczędzając Twój czas i pieniądze. Ale jak skutecznie zintegrować inną maszynę pakującą z istniejącym systemem? Tutaj pokażemy, jak działa maszyna pakująca w worki, ze szczególnym uwzględnieniem maszyny pakującej w worki ACEPACK i kilku przydatnych rekomendacji.

Październik 2023 Data wydania: If You Were a Factory (maszyna do pakowania toreb)

Pierwszą rzeczą do zrobienia przed zakupem maszyny pakującej w worki jest sprawdzenie przestrzeni w Twojej fabryce. Warto sprawdzić, ile masz miejsca, a także jakiego sprzętu obecnie używasz. Acepack ma maszyny pakujące w worki różnych typów i powinieneś wybrać maszynę napełniającą worki, która idealnie pasuje do Twojej obecnej konfiguracji. Podczas gdy wybór odpowiedniej maszyny jest ważny, jeśli chodzi o wybór maszyny, która pasuje do fabryki. Nasi eksperci są tutaj, aby pomóc Ci określić, która maszyna najlepiej odpowiada Twoim potrzebom i dostępnej przestrzeni.

Po wybraniu idealnej torby maszyna pakująca czas przygotować miejsce pracy, aby nowy sprzęt miał przyjazny i zorganizowany dom, co zapewni wydajność pracy. Upewnij się, że przestrzeń, w której umieścisz maszynę, jest czysta, sucha i wystarczająco duża, aby pomieścić sprzęt i zapewnić jego bezproblemową pracę. I nie podejmuj decyzji dotyczących układu bez przemyślenia, jak pracownicy będą się poruszać w przestrzeni. Acepack może pomóc nie tylko w ustawieniu maszyny, ale także w przeszkoleniu pracowników, aby wszystko działało płynnie od samego początku.

Korzystanie z maszyny do pakowania worków

Kiedy nadejdzie czas na zainstalowanie nowej maszyny pakującej w Twojej fabryce, niezbędna jest współpraca z firmą, która ją wyprodukowała. Acepack ma zespół inżynierów wysokiego szczebla, którzy przyspieszą ten proces. Oznacza to, że będą oni dostępni, aby pomóc od momentu zainstalowania maszyny do momentu przeszkolenia pracowników w zakresie obsługi samej maszyny, aż do jej prawidłowego użytkowania.

Twój zespół może być pewien, że nasi inżynierowie będą z nimi współpracować, aby zapewnić bezproblemową instalację nowej maszyny. Upewnią się, że wpasuje się ona w Twój obecny przepływ pracy, aby nie doszło do zakłóceń w Twoim procesie produkcyjnym. Przeszkolą również Twój zespół, aby upewnić się, że dokładnie wiedzą, jak obsługiwać nową maszynę. To szkolenie jest ważne, ponieważ uczy ich, jak optymalizować sprzęt. Ponadto po rozpoczęciu instalacji będziemy również kontynuować pomoc techniczną i usługi konserwacyjne, aby prace zbliżały się w przyszłości.

Wprowadzenie nowej maszyny pakującej do Twojego miejsca pracy

Najważniejsza część płynnego dodawania nowego maszyna pakująca ma plan. Ważne jest, aby dowiedzieć się, gdzie nowa maszyna wpasuje się w Twój obecny przepływ pracy i jak pomoże w ulepszeniu całego procesu. Pracownicy Acepack mogą pomóc Ci w opracowaniu tych planów i doradzić w kwestii integracji nowego sprzętu w Twojej fabryce.

Chociaż może to być zniechęcające zadanie, jedną rzeczą, którą możesz zrobić, aby upewnić się, że wszystko działa płynnie, jest upewnienie się, że Twój personel jest odpowiednio przeszkolony w zakresie korzystania z nowej maszyny. Obejmuje to szkolenie w zakładzie, które może zapewnić Acepack, a także zasoby szkoleniowe, do których pracownicy mogą uzyskać dostęp online, aby pomóc im nauczyć się korzystać z nowego sprzętu i go konserwować. Takie szkolenie zapewni, że w pełni wykorzystasz swoją inwestycję w maszyny, a Twoi pracownicy będą czuli się pewnie i kompetentnie, aby z nich korzystać.

Maszyna do pakowania worków do użytku

Poniżej przedstawiamy kilka przydatnych wskazówek, o których należy pamiętać, wprowadzając nową maszynę pakującą do swojej fabryki:

Zaplanuj z wyprzedzeniem: Rozsądnie jest zaangażować wszystkie strony na wczesnym etapie procesu. Poinformuj wszystkich zainteresowanych o nowej maszynie pakującej, aby zminimalizować wszelkie zakłócenia w działaniu.

Poznaj maszynę: Jeśli maszyna nie została jeszcze zainstalowana, zrób wszystko, aby lepiej ją zrozumieć. Wszystkie nasze maszyny są dostarczane ze szczegółowymi instrukcjami i instrukcjami od Acepack, które mogą się przydać.

Przeszkol swoich pracowników: Jednym z najważniejszych aspektów, aby nowa maszyna działała dobrze, jest upewnienie się, że zespół jest odpowiednio przeszkolony w jej obsłudze. Przed rozpoczęciem upewnij się, że wszyscy są zadowoleni z jej działania.

Serwis i konserwacja: Utrzymanie maszyny w dobrym stanie przez długi czas wymaga również planu konserwacji. W tym celu Acepack oferuje pełne wsparcie serwisowe i konserwacyjne dla wszystkich naszych maszyn.

Podsumowanie

Ogólnie rzecz biorąc, narzędzie do pakowania worków pomaga zmaksymalizować wydajność produkcji i zminimalizować czas i koszty. Współpraca z ekspertami Acepack sprawi, że cały proces zdalnie będzie dla Ciebie płynny i łatwy. Właściwe planowanie i szkolenie zespołu może zmaksymalizować produktywność przy jednoczesnym zapewnieniu bezpieczeństwa pracowników. Jeśli więc chcesz ulepszyć i udoskonalić swoją fabrykę, być może nadszedł czas, aby zainwestować w nową maszyna do pakowania w stojącą torbę i przenieś swoją linię produkcyjną na wyższy poziom.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

MK

MK

KA

KA

MN

MN

/images/share.png)